evranch_canada

- Beiträge

- 39

- Likes

- 43

Good evening,

I have seen several threads here about removing injectors, but in them, there was often debate and argument, and sometimes injectors being damaged or warnings about damage. It appears like it should be simple, but why is there so much debate and warnings?

I have the 812 service manual, I am familiar with diesel injectors. I have disassembled, cleaned and rebuilt them from tractors such as Case and Massey, but not this style.

So first I need to loosen the 30mm nut. This is not really a nut, but a hollow bolt that is threaded into the head, retaining the injector assembly. No special tool, just a big wrench.

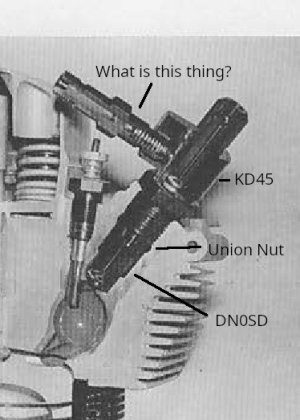

Then, I can simply remove the injector assembly from the head, pull it straight out. Something remains in the head that may need to be removed with a slide hammer... I have read comments saying it is the nozzle. But it doesn't appear to be the nozzle DN0SD, as this is held on with the union nut? What is it that is supposed to remain in the head? I don't see anything on the picture to be left behind. Or do you slide hammer the entire assembly if it is stuck with carbon?

I especially want to avoid the situation that happened to Harm long ago in this thread and was trying to understand what happened there. It appears the 30mm nut was destroyed, then the union nut unscrewed from KD45 and was left behind with DN0SD nozzle. This came apart because of twisting KD45 relative to the head, while the union nut was still retained inside by the 30mm nut? At least the damaged parts are supplied with the injector as long as you don't ruin the threads in the head, it looks like.

Finally the cracking pressure is set by adjusting the set screw underneath the leak-off pipe, which compresses an internal spring. As long as I don't disassemble or twist this part of the injector, the cracking pressure should not be changed. However if I need to remove the union nut, change DN0SD, or otherwise twist the main injector body and move the spring, I will need to use a pressure tester to reset the cracking pressure. Correct?

Also, what is that piece sticking out of the fuel inlet? Sometimes it's there and sometimes not in the manual, but it's there on my tractor. No documentation. Meant to damp noise or something? Safe to remove and clean it out?

Thank you again for your help, and especially if you took the time to read all this,

Alex

I have seen several threads here about removing injectors, but in them, there was often debate and argument, and sometimes injectors being damaged or warnings about damage. It appears like it should be simple, but why is there so much debate and warnings?

I have the 812 service manual, I am familiar with diesel injectors. I have disassembled, cleaned and rebuilt them from tractors such as Case and Massey, but not this style.

So first I need to loosen the 30mm nut. This is not really a nut, but a hollow bolt that is threaded into the head, retaining the injector assembly. No special tool, just a big wrench.

Then, I can simply remove the injector assembly from the head, pull it straight out. Something remains in the head that may need to be removed with a slide hammer... I have read comments saying it is the nozzle. But it doesn't appear to be the nozzle DN0SD, as this is held on with the union nut? What is it that is supposed to remain in the head? I don't see anything on the picture to be left behind. Or do you slide hammer the entire assembly if it is stuck with carbon?

I especially want to avoid the situation that happened to Harm long ago in this thread and was trying to understand what happened there. It appears the 30mm nut was destroyed, then the union nut unscrewed from KD45 and was left behind with DN0SD nozzle. This came apart because of twisting KD45 relative to the head, while the union nut was still retained inside by the 30mm nut? At least the damaged parts are supplied with the injector as long as you don't ruin the threads in the head, it looks like.

Finally the cracking pressure is set by adjusting the set screw underneath the leak-off pipe, which compresses an internal spring. As long as I don't disassemble or twist this part of the injector, the cracking pressure should not be changed. However if I need to remove the union nut, change DN0SD, or otherwise twist the main injector body and move the spring, I will need to use a pressure tester to reset the cracking pressure. Correct?

Also, what is that piece sticking out of the fuel inlet? Sometimes it's there and sometimes not in the manual, but it's there on my tractor. No documentation. Meant to damp noise or something? Safe to remove and clean it out?

Thank you again for your help, and especially if you took the time to read all this,

Alex

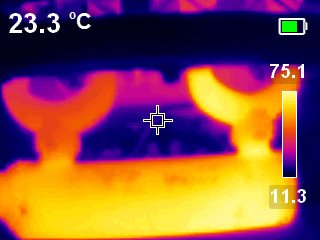

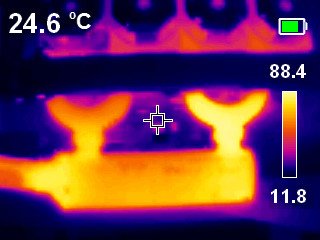

However working on a cold day makes it easy to generate big temperature differentials with the torch, sometimes this works well on things like steering parts.

However working on a cold day makes it easy to generate big temperature differentials with the torch, sometimes this works well on things like steering parts.